Optimal Timing for Concrete Floor Polishings

Concrete floor polishings are a popular choice for enhancing durability and appearance in commercial and industrial spaces. Proper timing ensures optimal results and longevity of the finish. The right time to perform polishings depends on factors such as the current condition of the concrete, ambient conditions, and usage patterns.

Polishing should be done after the concrete has fully cured, typically 28 days post-installation, to ensure stability and proper hardening.

Ideal times are during moderate weather conditions, avoiding extreme temperatures and high humidity which can affect curing and polishing quality.

Performing polishings before occupancy or heavy use minimizes disruptions and allows the finish to set properly.

Scheduled polishings every few years help maintain the surface’s appearance and protective qualities.

Image of a polished concrete floor during the finishing process.

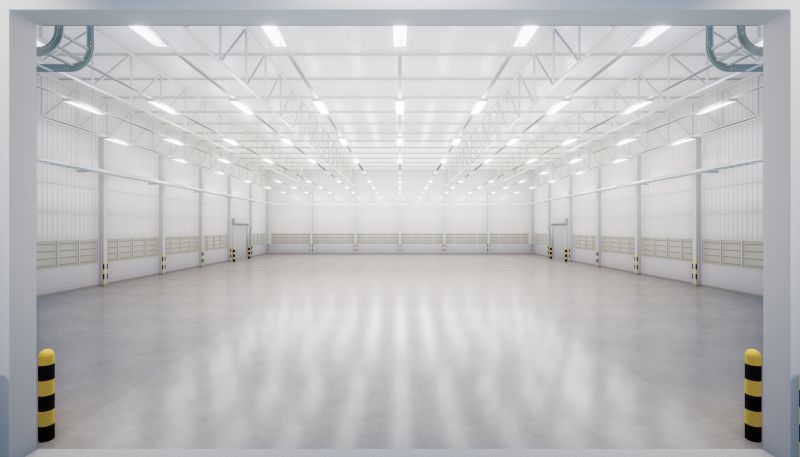

Image showcasing a smooth, reflective concrete floor surface.

Image of polishing machines working on a concrete surface.

Ways to make Concrete Floor Polishings work in tight or awkward layouts.

Popular materials for Concrete Floor Polishings and why they hold up over time.

Simple add-ons that improve Concrete Floor Polishings without blowing the budget.

| Factor | Optimal Timing |

|---|---|

| Concrete curing period | After 28 days of curing |

| Seasonal weather | Spring or fall for moderate conditions |

| Post-repair | Immediately after resurfacing or repairs |

| Maintenance schedule | Every 2-3 years for optimal appearance |

| Building occupancy | Before initial occupancy or during low-traffic periods |

| Humidity levels | When humidity is controlled and stable |

| Temperature range | When ambient temperature is between 50°F and 85°F |

| Surface condition | When the surface is free of cracks and debris |

Concrete floor polishings improve surface durability, enhance appearance, and provide resistance against stains and wear. Proper timing maximizes these benefits, ensuring long-lasting results. Regular maintenance and timely polishings can extend the lifespan of the concrete surface, reducing the need for costly repairs.

Detailed view of a high-gloss polished concrete surface.

Image of a warehouse with a polished concrete floor.

Entryway featuring a polished concrete floor.

Tools used in the concrete polishing process.

High-end options that actually feel worth it for Concrete Floor Polishings.

Finishes and colors that play nicely with Concrete Floor Polishings.

Little measurements that prevent headaches on Concrete Floor Polishings day.

A 60-second routine that keeps Concrete Floor Polishings looking new.

Interested in scheduling concrete floor polishings? Filling out the contact form provides a convenient way to request more information and discuss specific needs. Proper timing and maintenance can significantly enhance the appearance and durability of concrete surfaces.